New Beet Sugar Centrifuge Screens – Yield Saving!

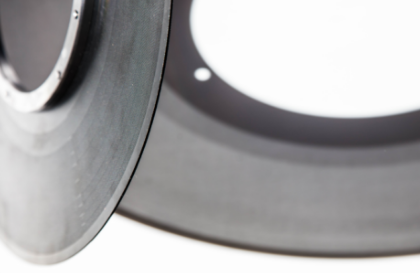

In 1988 ActionLaser began the filtration journey into the Australian sugar cane market with the world’s first chrome coated stainless steel centrifuge screen. Soon after – we began selling to sugar cane customers in South America and South Africa.

Around this time, we built enduring commercial relationships with major beet customers in the UK, Switzerland and USA.

We have been “Going the distance” for over 35 years supporting our loyal customers and constantly investing in new technology. Now, we are launching new technology to bring yield improvements to both Beet and Cane customers.

We have been “Going the distance” for over 35 years with appreciation for and respect for our loyal customers.

First, let us travel back to the 90’s.Pioneering scientists discovered that ActionLaser’s stainless steel centrifuge screens saved sugar mills hundreds of tonnes of sugar through increased sugar crystal yield. Today, a typical Australian sugar mill crushes 1.4m tonnes of cane per season [or campaign] and will generate an extra A$200,000 dollars [at $500 per tonne] a year using ActionLaser centrifuge screens versus chrome nickel screens. See attached scientific research paper…Read More link

Chrome Nickel users miss out because; “an inherent weakness of the chrome-nickel screen with high susceptibility of the nickel base to the corrosion by salt present in molasses. This leads to an increase in the slot width as the chromium surface peels off progressively and results in the increased loss of sugar”.

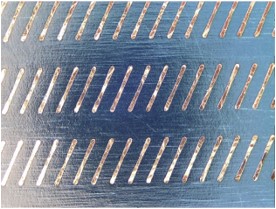

The main features of laser-cut or laser drilled screens as summed up by the Scientists as:

- The hard chromium surface-coating on the stainless-steel base does not flake off easily.

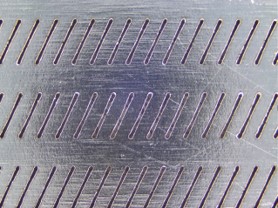

- The screen slots are tapered and have sharp, hardened working edges and high relief angles to achieve high separation efficiencies without clogging.

- High resistance to enlargement of the slots due to hardened working surfaces, and resistance to damage by foreign objects [Vs chrome-nickel].

- Uniform thickness of screens.

- Apart from the mechanical benefits, the laser-cut screen reduces sugar loss by 1-3 points in molasses screen, blinding and downtime.

Today, we are launching new laser drilling optics technology where the “laser-drilled” screens have parallel sides with rounded slot ends versus older generation elliptical shaped slot with sharp pointed ends. This means todays screens give improved liquid flow, increased open area and are much stronger and give better life.

New Beet Customers seeking thousand-dollar yield improvements!

Today, researchers and sugar beet technologists are undertaking trials in Europe and North America to determine if the 1.3 point sugar recovery is applicable from beet molasses as seen in cane molasses.

Higher financial returns from increased sugar yield, significantly longer laser screen life and enhanced sugar mill productivity means ActionLaser stainless steel screens are essentially “free” versus the cost of 3-4 sets of chrome nickel screens per season.

Our Future.

ActionLaser has grown from a technology pioneer to a global advanced manufacturer of laser drilled filtration technology. Our products give optimal performance in many applications. We are Australian owned and proudly an Australian manufacturer and exporter of world class products.

Today, our laser drilling technology is sought after globally by industries ranging from mineral processing to foods, pharmaceuticals, water recovery, aerospace, plastic recycling, and many other segments. We remain 100% focused on our customers.

Why does ActionLaser have the unusual logo for our MeltFilter business?

It is “Xanthorrhoea Australis” – an native Australian Grass Tree, which has these primary characteristics: Surv...

Read MoreUK customer’s like MeltFilters by ActionLaser

ActionLaser’s Production Manager, David Pask recently visited 12 plastic recycling operations in the United Kingdom. S...

Read MoreLaunches in the UK

ActionLaser has teamed up with Andrew Taylor (CEO) and Ben Peacock (Business Development Manager) of Sonic Solutions to ...

Read MoreMineral Processing

Going the distance – is what we always do. ActionLaser originated through the development of specialized laser drillin...

Read MoreSugar Cane Processing

Since 1988, our regular presence at the Australian sugar mills and refineries is appreciated by our customers. Our goal ...

Read More