Sugar Cane Processing

Since 1988, our regular presence at the Australian sugar mills and refineries is appreciated by our customers. Our goal is to visit our sugar mill customers twice a year. We fly from our manufacturing base in Sydney to Cairnes and drive over 4000 kilometers via Mossman (Far North Queensland), along the Queensland coast to NSW Northern Rivers then on to Sydney. The biannual long distance overland sugar mill trips have only been broken by the recent Covid induced restrictions limiting our ability to visit our core customers. We are now back and are warmly welcomed by our home industry partners and customers. We will continue to enhance the closely developed relationships we have as a reliable supplier to our partners in the Australian sugar industry. Distance is no barrier to customer service.

Increasing sugar recovery or sugar yield using stainless steel fugal screens.

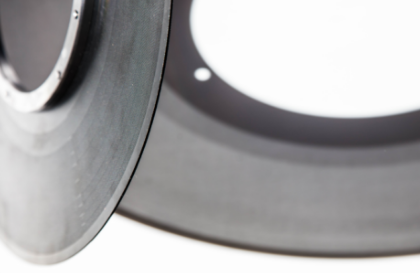

Amongst the many commercial and production challenges facing the Australian sugar industry in the 1980’s, was the needs to have improved in productivity and yield recovery in the low-grade centrifuges. This need created the development and cooperation between the Australian sugar mills and the CSIRO to find better ways for recovery of sugar crystals. Crystal loss occurs when softer nickel working screens distort across the backing screens causing a widening and spreading of the slot widths. This action also causes the hard chrome layer to delaminate off the softer nickel sub straight. The end result is rapidly increased wear, reduced sugar yield [increased sugar crystal loss] and reduced working screen life.

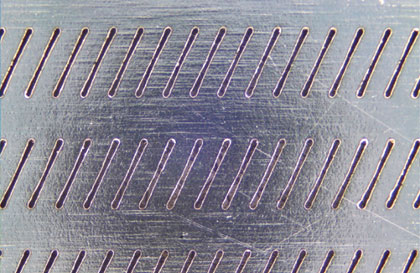

The development of the first laser perforated slotted screen made from chromed stainless steel proved to be a major success. Made with shorter slots and drawing on the structural strength and stiffness of stainless steel the screens optimize crystal recovery and dramatically increasing working life of screens. Today the accuracy and dimensions of slot and open area sets laser screens apart as the benchmark of the industry.

The versatility of the laser screen has given rise to deployment in high grade continuous centrifugal operations due to their impressive yield recovery, durability, and screen longevity.

Partner with the Australian Sugar Cane Mills.

ActionLaser has been a trusted partner to the Australian sugar industry since its first orders of working screens from the industry starting with Victoria Mill and Babinda Co-op in March 1989. International orders soon followed from the US, Europe and India following later in the same year.

Our presence in the industry has seen ActionLaser partner with other leaders of technology such as SRI, where we developed, manufactured, and supplied jigger tubes for both local and international customers.

In addition, we are supplying batch centrifugal working and backing screens, mud filter screens and self-cleaning filter systems for various applications to our local Australian and global sugar mills.

From cane to beet and betaine processing applications, ActionLaser laser screens are seen by both manufacturers and sugar producers as the benchmark to the sugar industry worldwide.

Our Future.

ActionLaser has grown from an Australian technology pioneer to a global advanced manufacturer of laser drilled filtration technology. Our products give optimal performance in many applications. We are Australian owned and proudly an Australian manufacturer and exporter of world class laser screens and filters.

Today, our laser screen technology is sought after globally by industries ranging from mineral processing to foods, pharmaceuticals, water recovery, aerospace, and plastic recycling amongst many other segments. We remain close to our core customers whilst forging a global footprint for Australia with exports now exceeding 80% of our manufacture.

Steve Greer

Sales Team Head

Why does ActionLaser have the unusual logo for our MeltFilter business?

It is “Xanthorrhoea Australis” – an native Australian Grass Tree, which has these primary characteristics: Surv...

Read MoreUK customer’s like MeltFilters by ActionLaser

ActionLaser’s Production Manager, David Pask recently visited 12 plastic recycling operations in the United Kingdom. S...

Read MoreLaunches in the UK

ActionLaser has teamed up with Andrew Taylor (CEO) and Ben Peacock (Business Development Manager) of Sonic Solutions to ...

Read MoreMineral Processing

Going the distance – is what we always do. ActionLaser originated through the development of specialized laser drillin...

Read MoreNew Beet Sugar Centrifuge Screens – Yield Saving!

In 1988 ActionLaser began the filtration journey into the Australian sugar cane market with the world’s first chrome c...

Read More